Why Bugatti Says You Can’t “Just 3D-Print” Parts for a $2 Million Hypercar

Bespoke for a Reason

At a certain level of automotive manufacturing, things take a very sharp turn towards unbelievably custom parts building. What this means is that the more expensive and sought-after hypercar models require very specialized production methods that no mass manufacturer can provide.

That type of production applies to a brand like Bugatti, the go-to for extreme performance, luxury, and brand presence. When one owns a Bugatti, it’s a statement to the world that “I own the very best.” So it isn’t a surprise that if someone claims something “iffy” about the brand, it ticks some people off, in this case, the owner himself, Mate Rimac.

High Maintenance

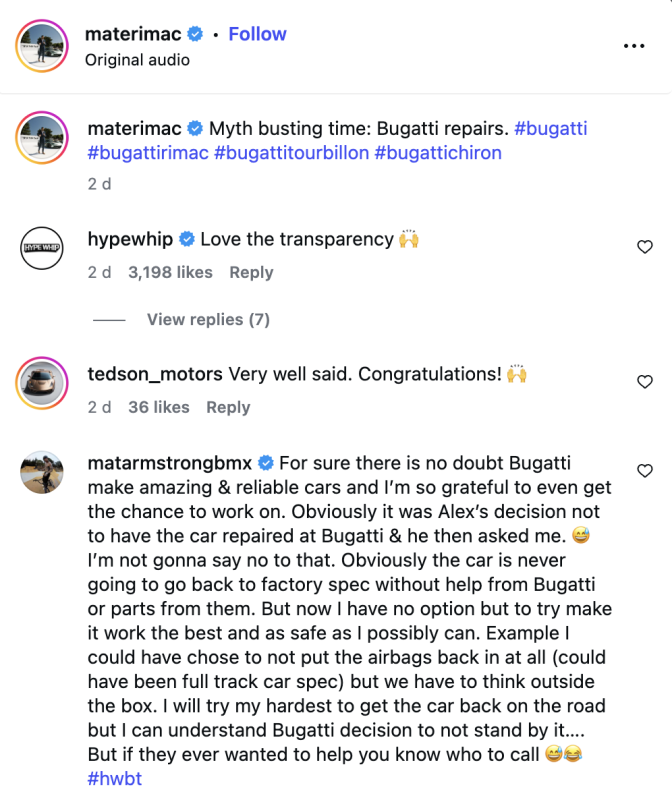

YouTuber Mat Armstrong has gone on record to say something very controversial. He claims that when it comes to repairing Bugattis, one can simply 3D-print replacement parts. What makes this claim outrageous is that any car made by the brand costs upwards of $2 Million. In any case, the claim has gone viral and has prompted a response from a brand representative, none other than the owner himself, Mate Rimac.

Rimac is a very successful automotive mogul, getting his reputation for first building the extremely fast Rimac EV hypercars. He’s now the CEO at Bugatti-Rimac and is one of the most outspoken executives in the industry. In response to those claims, he has responded by posting a video on his personal IG account, wherein he dispels some claims circulating on the web.

But first, he addressed the rumors about the price of some replacement parts. It has been claimed that headlights, for example, cost $150,000 apiece, when in fact they only cost $25,000 each. Furthermore, he says prices are high because their goal is to have current Bugatti models last for 100 years, just like the brand’s classic models from eons ago.

3D Printed Parts?

Rimac then proceeded to answer Armstrong’s claims that parts can be 3D-printed for the Chiron. Rimac said that while they themselves use 3D printing as a component of part production, their process works because of the huge amounts of money invested in the R&D required to make parts. Not to mention that simply 3D-printing parts at home is not recommended for cars costing millions of Dollars.

While Mr. Armstrong is entitled to his opinion, he is in the business of YouTube and, as such, has used his platform to raise what he claims to be issues regarding the maintenance of his Chiron. The fact is, those who can fork over the cash for a brand-spanking new Bugatti can, with almost 100% certainty, pay the amount required to keep them running, without “shortcuts.”